The emergence of AI is permanently changing every aspect of modern manufacturing, turning data into decisions and machines into smart collaborators.

According to NUM (National Association of Manufacturers), 72% of manufacturers report lower costs after implementing artificial intelligence technology. It’s being used to predict equipment failures and support maintenance, automate quality control, optimise supply chains, and even support sustainability goals.

In this article, you'll learn how artificial intelligence is used in the manufacturing sector, what challenges it brings, the benefits it offers, and how to get started with it, all within the broader framework of Industry 4.0.

- Discover how manufacturing evolved from steam engines to Industry 4.0.

- Learn about key technologies and use cases of AI in manufacturing.

- The role of cobots, digital twins, and augmented reality in production.

From the industrial age to the intelligent industry

Industry 4.0, or the Fourth Industrial Revolution, refers to the entire digital transformation of manufacturing, and it has been one of the major shifts since the steam engine.

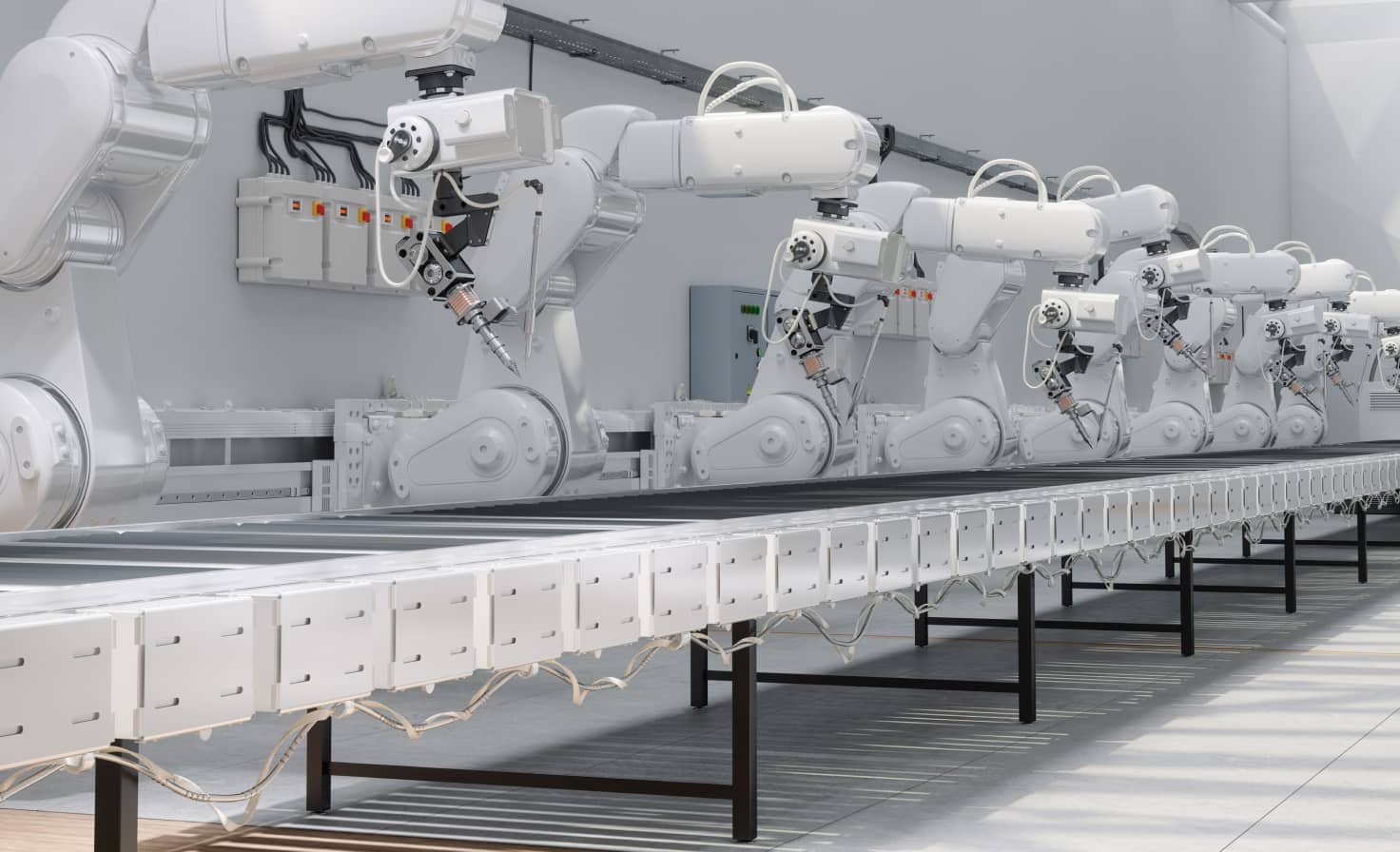

This new phase in manufacturing is driven by artificial intelligence, which enables factories to optimise production with unprecedented flexibility and agility.

AI in manufacturing uses machines and smart technology for tasks that normally require human involvement. Artificial intelligence in manufacturing can predict events before they occur, thanks to machines' ability to analyse data and identify patterns. The factories use data and automation to work faster and with less waste. The combination of AI and smart machines is called smart manufacturing.

Instead of replacing human input, AI in manufacturing industries offers solutions for quality control, analytics, predictive maintenance, automation, and more.

AI technologies applied in manufacturing for operational efficiency

- Computer vision: Powers visual inspection, traceability, process tracking, and defect detection. It processes images or videos to verify product quality, read barcodes, or monitor production lines in real time.

- Natural language processing: Used to automate reports, interpret alarms, and support operators via virtual assistants. NLP allows systems to understand human language, facilitating communication between machines and people.

- Time series analysis: the analysis of a historical series of values and forecasting those values into future periods, such as predicting prices and sales, weather conditions, etc.

- Signal processing: the purpose is to transform and clean the signal data by building models above it, such as automated speech recognition, speech synthesis, sound classification, and up-to-modern trends with music generation.

- Recommender engines: the systems that filter and suggest products based on usage or purchasing patterns. For example, they recommend stock-keeping units (SKUs) to increase the average order size or optimise product bundling.

- Anomaly detection: systems that focus on detecting unusual samples and deviate from the most common patterns. They can be built using unsupervised machine learning.

- General optimisation: a family of algorithms that focuses on finding the extrema or most efficient point in any activity and resource curves such as planning routes (minimising distance/fuel/time), workforce (salary optimisation), or revenue/income maximisation needs.

- Expert systems: Employed in fault diagnosis and decision support. These AI agent-based systems mimic expert human reasoning to identify issues and recommend corrective actions.

Use cases of AI in manufacturing

| Application | AI Impact |

|---|---|

| Predictive maintenance | Uses sensor data to predict equipment failures Schedules repairs to prevent downtime Reduces maintenance costs Extends machine lifespan |

| Quality control | Uses computer vision for automatic product inspection Detects defects in real time Improves product consistency and reduces waste Accelerates inspection processes |

| Supply chain management | Predicts demand and ordering and delivery processes Monitors supplier performance and delivery Supports production processes Enhances responsiveness to market changes |

| Robotics & collaborative robots (Cobots) | Automate repetitive or hazardous tasks Adapt to changing work environments Combine human flexibility with robotic precision Increase safety by detecting human presence |

Companies using AI in manufacturing

- Coca-Cola, HP, and Hologic use AI to cut downtime and avoid unnecessary repairs.

- IBM and Amazon rely on predictive maintenance to keep their industrial operations running smoothly.

- Ford uses cobots for glueing and quality control.

- Samsung uses AI-powered robots and automated systems in its South Korean plant to handle the assembly process, material transport, and quality checks.

How AI is solving challenges in manufacturing

Preventing downtime

Unexpected equipment breakdowns often cause production stops and lead to high costs from repairs and lost time.

AI solution: Predictive maintenance detects early warning signs instead of reacting to breakdowns. Manufacturers can schedule maintenance of machines ahead of time and avoid costly delays.

Reducing waste

Small defects can cause materials to be wasted, leading to product recalls.

AI solution: Advanced vision technology detects real-time defects and helps to maintain consistent product standards.

Making supply chains smarter

Global disruptions, demand swings, and material shortages have complicated supply chain planning.

AI solution: AI tools analyse large volumes of supply chain data to predict demand and flag risks. This means better planning and a supply chain that adapts quickly to change.

Tackling sustainability goals

Manufacturers must follow environmental regulations with the help of sustainability consulting.

AI solution: AI-powered systems track energy consumption to reduce environmental impact. For example, smart energy management software can shift usage away from peak hours.

According to McKinsey, advances in AI, machine learning, and data analytics reduced machine downtime by 30–50%. AI-powered machines handle simple, repetitive tasks like assembling parts or inspecting products, letting workers focus on more complex and creative work.

AI technology predicts when machines need repair by analysing real-time sensor data with AI algorithms. It also allows us to avoid machines breaking down and save money. AI reduces waste using materials more efficiently and saves energy through smart monitoring.

Vast amounts of manufacturing data from machines, supply chains, and production lines are analysed, giving managers up-to-the-minute insights on everything from machine health to inventory levels.

Greater accuracy can be achieved by analysing historical sales data along with current market trends, seasonal patterns, and external factors like economic indicators or competitor activity. For example, AI detects a sudden spike in online interest for some products and adjusts production schedules.

Implementing AI in manufacturing

Integrating AI into manufacturing companies takes careful planning. The first step is to find areas where AI can add value. Once these targets are clear, companies need to collect the relevant data to train AI systems. Data quality is the foundation for training machine learning models.

Then, a pilot project is launched to test the solution that can later be scaled across production facilities. Pilot projects allow teams to test AI tools and learn from the results.

Finally, it’s important to make sure AI tools fit into existing systems. Smooth integration helps teams get real results faster as AI becomes a long-term part of daily production operations. As AI is increasingly adopted, both machines and employees develop. Training and updated tools help teams collaborate more effectively with the technology.

How to use gen AI in manufacturing

Generative AI speeds up the design process by quickly creating multiple design options based on performance and cost. It suggests designs that reduce material waste and simplify production, helping companies lower development costs.

- Machine monitoring: Gen AI helps predict equipment failures early, reducing breakdowns and maintenance costs. It analyses machine data and suggests fixes in simple language.

- Customer service automation: Gen AI supports personalised responses to customer queries, which improves loyalty.

- Document search and summarisation: Key information is quickly extracted from complex manuals and sales documents.

- Product and content matching: Sales and stock data are analysed to recommend the most suitable products to customers.

- Supply chain support: Insights into suppliers, materials, delivery schedules, and sustainability are provided to help businesses make better sourcing decisions.

The future of AI in manufacturing: key trends

AI will become more deeply integrated into every stage of production in the manufacturing sector. The main reasons for growth in the AI manufacturing market are the need to improve supply chains and the growing demand for customised products across different industries.

Intelligent manufacturing systems will use real-time data and machine learning to make quick decisions on the factory floor. Digital twins will help predict problems and reduce costly mistakes. Generative AI is also becoming more popular for improving product design.

Smart operations: digital twins and augmented reality

Virtual replicas of a system or process are called digital twins. In manufacturing, this means creating a real digital model of a production line, machine, or product. This model behaves like a real one and receives data from sensors in the physical system.

Paired with augmented reality, digital twins visualise system performance for frontline workers who carry out maintenance. Designers can use AR to see 3D versions of products before they're built. In training, workers can learn faster by following interactive guides right in front of them.

Results improve when AI is added to the mix because AI-powered digital twins learn from past data and suggest improvements automatically. Digital twin technology and AR help companies cut costs and react quickly when customer demands, or production needs change.

Robots and Cobots in production

Traditional robots are stationary machines used in large-scale operations with high volumes and repetitive tasks, such as handling payloads at high speeds. Robots operate independently and replace human workers.

But Cobots, or Collaborative robots, are designed to work with humans in a shared workspace. Cobots are small and mobile and are installed on a movable workstation. AI makes them see what's around them and learn from experience. They help with tasks that require flexibility and precision, such as assembling small parts.

Final thoughts

AI integration helps manufacturing companies support product development and streamline supply chain operations.

To stay ahead of competitors, companies have to respond faster to market changes and shift to meet customers' needs. To implement AI technology successfully, manufacturers need to identify the manufacturing solutions for their specific challenges, determine how to collect and use data and decide where AI can improve existing processes. Our team will guide you through every step of the process of AI implementation, especially with regard to adoption challenges, risks, and known failures.

FAQs

AI is used to improve production by predicting equipment failures, automating tasks, checking product quality, forecasting demand, and supply chain optimisation.

AI will become even more integrated, with smarter automation, predictive systems, and advanced design tools, enhancing efficiency in factories.

AI is not taking over manufacturing but is transforming it by automating tasks and supporting human workers rather than replacing them.

Industry 4.0 is the broader concept that refers to the entire digital transformation of manufacturing using technologies like IoT, AI, cloud computing, and automation. Smart manufacturing is a key part of Industry 4.0, focusing on applying smart systems to improve overall operational efficiency.