Industrial automation engineering – the basics

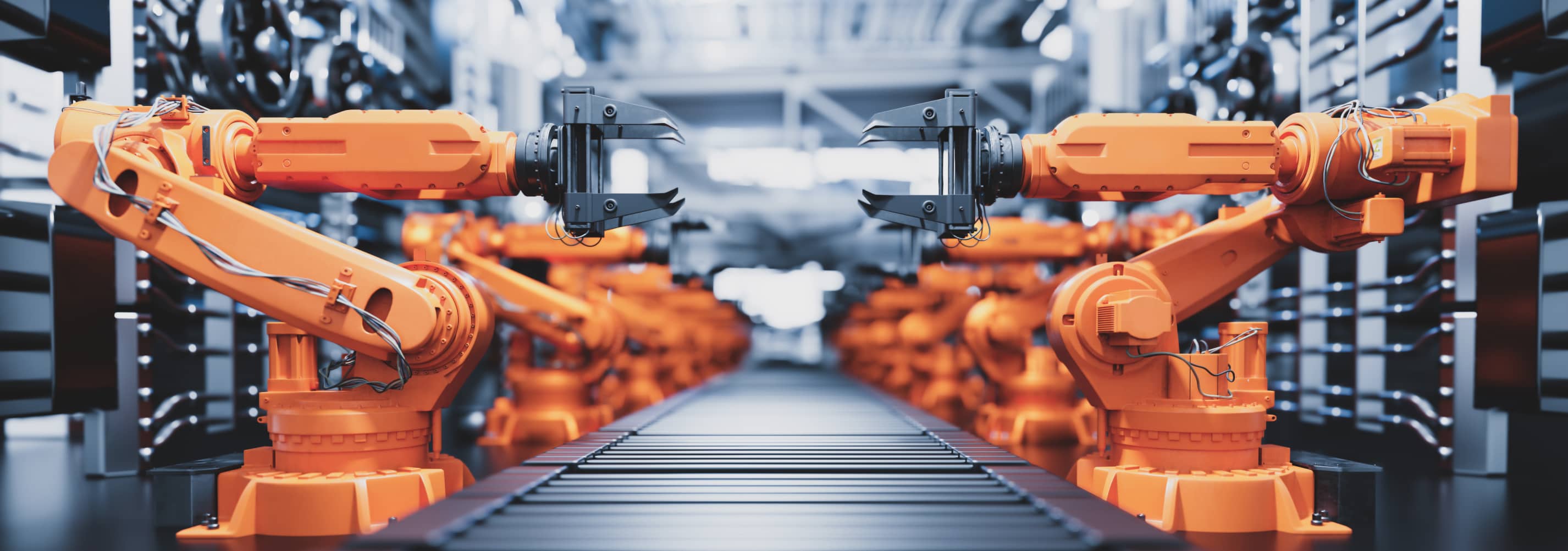

Industrial automation engineering is the process of designing, implementing and maintaining automated systems in an industrial plant. It involves the use of computers and software to control machines and procedures and design their architectures.

These days, many companies rely on industrial automation engineers and use custom software development services to design and implement systems that can automate tasks that humans previously performed. It has helped many industries become more efficient, reliable, and cost-effective.

There are four main types of industrial automation systems: fixed, programmable, flexible and integrated. Each type has its benefits and drawbacks, so you have to consider your business needs before deciding.

1. Fixed automation

Fixed automation is specifically designed to carry out a single process or task, making it best suited for repetitive and well-defined tasks. This type is typically used in manufacturing settings, where the equipment is fixed with a particular set of functions, and there are rarely any changes to these operations.

However, the entire system must be redesigned and rebuilt if any changes are required in the production process, including changes in the components' design or the raw materials. It can be a very costly and time-consuming process. Moreover, if there are any problems with the equipment, it can be complicated to troubleshoot and repair.

2. Programmable automation

By entering computer code into the system, programmable automation components can be controlled to perform multiple functions quickly and easily. This makes them much more adjustable than fixed tools, which means they can be customised to meet the specific requirements of each product.

Programmable automation solutions are widely used across industries today, but it is particularly well-suited for the packaging industry and material handling applications. Programmable automation can quickly change tasks; however, this type can be less reliable and may require more maintenance.

3. Flexible automation

Flexible automation is the best of both worlds: the reliability and precision of fixed automation, with the adaptability and flexibility of programmable automation.

With flexible automation, companies get computer-controlled systems that can seamlessly adjust to changing needs quickly and easily. This makes it perfect for food and beverage production industries, where recipes or ingredients may need to be changed frequently.

There is often confusion between flexible and programmable automation, as they are quite similar. However, users are typically limited to batch production or low-variation tasks with programmable automation. Meanwhile, flexible automated systems can be adjusted for different kinds and levels of complexity when it comes to the manufacturing process.

4. Integrated automation

It combines two or more types of automation to create a custom solution, which is developed to manage and streamline the use of tools and processes to achieve optimal results with minimal human effort.

This type of automation is often used in complex manufacturing settings where multiple processes must be coordinated. They're usually used in large factories with many machines and can be expensive. However, they're very efficient and can help to improve productivity.

How industrial automation engineering can benefit your business

The use of machines, robots, and automated system solutions can obviously add value and assist businesses in attaining new levels of efficiency and productivity. However, let's examine some key benefits of industrial automation engineering.

- Improved productivity. Automated assembly lines comprise workstations connected by transfer lines; each workstation is responsible for one stage of the manufacturing process. Robots can be used to replicate many human actions, enabling continuous production. By automating tasks that workers traditionally do, a company can free up time and resources to focus on more critical tasks. This increased efficiency can lead to a significant boost in productivity.

- Optimized costs. The application of robotics, AI systems, and other innovative technologies can help minimise production, labour costs and the costs associated with errors and downtime. In addition, automated systems often require less maintenance than their manual counterparts, further reducing costs over time.

- Enhanced quality. A company can achieve a high-quality outcome by automating some steps in the manufacturing process which are difficult or impossible for humans to do accurately. It includes tasks such as welding, measuring, and packaging. Automation allows the creation of more complex items, such as electronic goods and pharmaceuticals. It can also maintain error control along the way and stop production until one is corrected.

- Higher workplace safety. In the manufacturing industry, the safety of workers is a top priority. IoT devices can help us track machinery damage, toxic material, or vehicle mishap, which help identify potential hazards and take steps to mitigate them.

For instance, automation can be introduced as a part of automotive software engineering services, to allow enterprises in this sector to leverage advanced tools to control workers' health, identifying risks such as toxic fumes, fatigue and stress levels. Business owners can ensure that their employees are safe by using this information for security reasons. Ultimately, this will improve working conditions and reduce insurance costs.

Getting the most out of industrial automation engineering

As you begin to automate your processes, it's crucial to have the right team in place to help you navigate the challenges and opportunities that come with it. Here are some tips for leveraging the team of automation engineers:

- Identify the problem you're trying to solve. Before you can automate anything, you need to identify the problem you're trying to solve. If you are not clear about your objectives and goals from the very start, you won't be able to develop an effective solution. An industrial automation engineer will help you spot the inefficiencies in your current process and define what impact these inefficiencies have on your organisation.

- Understand the business case for automation. Once you've identified the areas for improvement, an experienced automation engineer will help to understand the potential gains of automating a process. Decreased labour costs, quality control, and growth of the company's profitability are just a few points to consider when assessing the business case for automation.

- Choose the right technology. When it comes to automation, there are many different technologies available, from industrial robots to data analysis and programmable logic controllers. It's essential to choose the right one for your requirements. An experienced technical team can help you choose from the options existing on the market or develop a custom solution that best fits your needs.

- Implement the automation technology. When you've selected the right technology for your plant, it's essential to work with a team of experts to get the most out of your investment. Make sure you have a clear plan for how you want to implement automation so that the process goes smoothly and you can maximise the benefits.

If you're looking to increase your efficiency, cut costs and drastically improve workplace safety, automation engineering is the way to go. With the help of an experienced automation engineer, you can develop and deploy an automation solution that will provide an optimal ROI and the best results.

Related Insights

The breadth of knowledge and understanding that ELEKS has within its walls allows us to leverage that expertise to make superior deliverables for our customers. When you work with ELEKS, you are working with the top 1% of the aptitude and engineering excellence of the whole country.

Right from the start, we really liked ELEKS’ commitment and engagement. They came to us with their best people to try to understand our context, our business idea, and developed the first prototype with us. They were very professional and very customer oriented. I think, without ELEKS it probably would not have been possible to have such a successful product in such a short period of time.

ELEKS has been involved in the development of a number of our consumer-facing websites and mobile applications that allow our customers to easily track their shipments, get the information they need as well as stay in touch with us. We’ve appreciated the level of ELEKS’ expertise, responsiveness and attention to details.