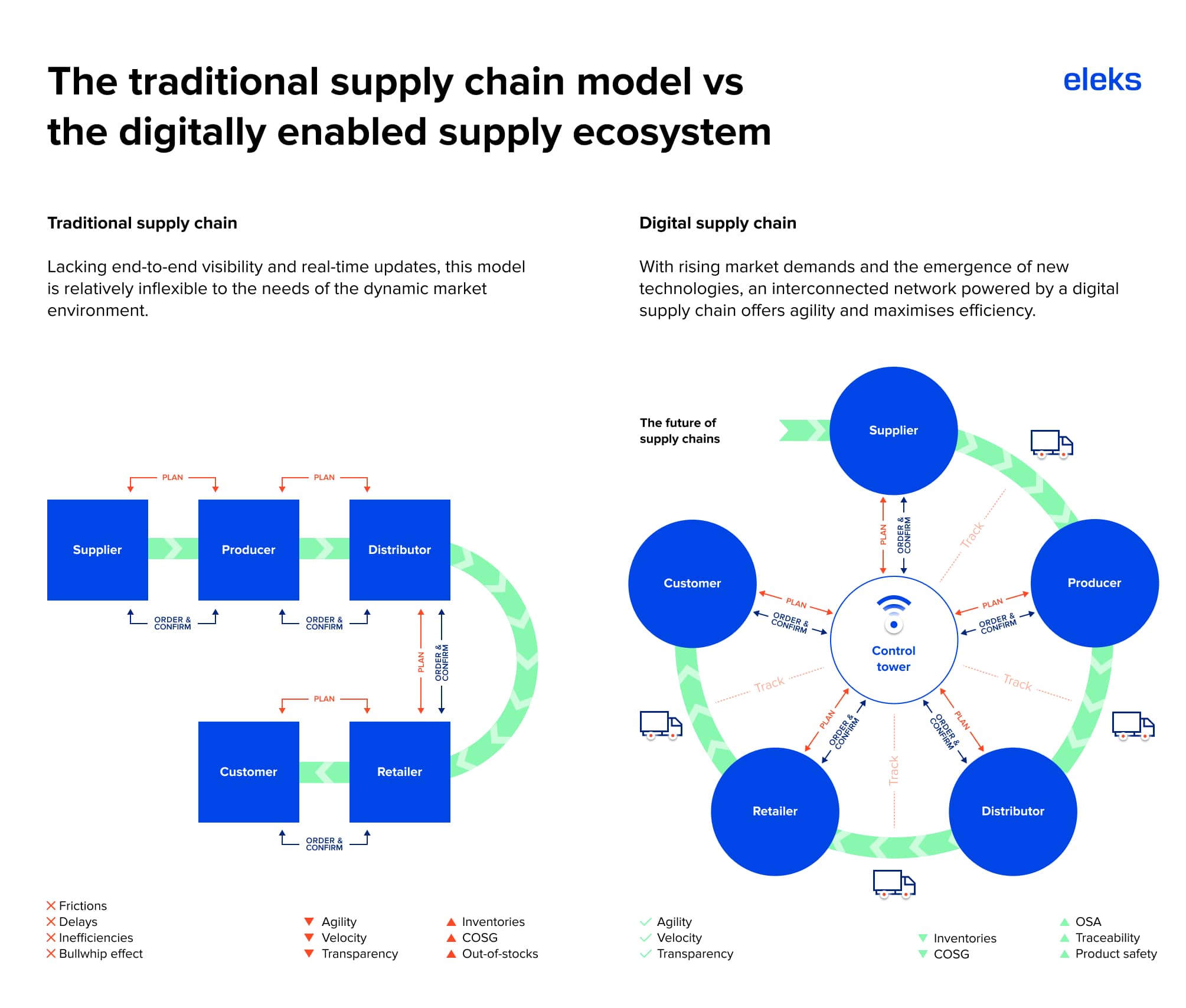

The traditional supply chain can be outlined as a linear model that is useful in a predictable and consistent environment. However, the uncertain times we are currently experiencing requires the adoption of a new supply chain model that allows organisations to be more responsive and agile to survive and lead the market. Supply chain 4.0 is the application of the Intelligence of Things, big data combined with custom logistics software development, data science, digital connectivity and many other smart technologies brought by the fourth industrial revolution.

Innovative technologies reorganise the traditional model, change how information flows within the chain and help to achieve greater business success through automation and digitalisation. Global organisations like Adidas, Maersk Line, Volvo, Port of Hamburg and Decathlon already use IoT in their supply chain operations to get valuable insights into things like inventory, logistics and warehousing.

Source: supplychainbeyond

Key benefits of supply chain 4.0

Digital transformation of the supply chain can bring a company a plethora of benefits from better end-to-end visibility and improved decision-making to higher operational effectiveness and minimisation of expenditure.

Here’s more about the top advantages of the digital supply chain:

Espouse end-to-end transparency.

With the digital supply chain, data exchange between an organisation, multiple suppliers and customers becomes more effective. Real-time asset tracking powered by IoT, cloud-based dashboards and other tech solutions make it possible to establish an item's precise location. Organisations can see all updates added to the digital ecosystem, leading to ordering accuracy, traceability and efficiency.

More accurate forecast approach.

Predictive analytics has the potential to reduce forecasting errors by 10% to 20%. Fuelled by AI and machine learning, predictive analytics evaluates historical information about demand, current market trends, weather conditions and other data to provide statistics-based demand forecasts and optimise inventory. Predictions can be carried on a monthly, weekly or even daily basis depending on the product, helping to prevent out-of-stock situations and ensuring on-time delivery. Moreover, performing real-time analysis of a constantly changing market allows organisations to adapt to prevailing trends and stay flexible.

Enhanced supply chain management.

According to the Boston Consulting Group, digital supply chain management offers a 25% faster response to market demand changes. Process management, supply and demand planning, cash flow and other underlying supply chain processes can be managed within one digital ecosystem. Custom warehouse management systems that use IoT and data analytics can optimise the warehouse space by providing insights into shipping and picking. Immutable records offered by blockchain technology and smart contracts allow supply chain optimisation, guarantee secure and automated transactions, and increase the visibility of purchases and transactions in supply chains.

Improved customer experience.

In the US, poor customer service lead to an average $62 billion loss annually. The end-to-end visibility guaranteed by the digital supply chain increases the knowledge of employees in customer-facing positions. Customers can receive an immediate response about product availability and detailed information about the order, improving the overall experience and bottom-line growth.

Source: McKinsey

Supply chain 4.0 use cases throughout industries

The disruption in today’s business environment makes digital supply chain adoption a necessity rather than an option. And while many organisations are just considering the benefits, some have already implemented a digital supply chain and proven its capabilities. Here are a few applications of supply chain 4.0:

1. Manufacturing

Digital technologies can help to mitigate the disruptions caused by the pandemic and boost operational efficiency and continuity. For instance, wearables like augmented-reality glasses can help employees receive or render remote assistance, leading to reduced maintenance time. Machine vision algorithms can conduct an automatic quality assurance by analysing images for specific results.

It is unlikely that 3D printing will substitute the traditional manufacturing process. However, it can be applied as a cost-effective solution for producing personalised items. Dr Scholl, a manufacturer of foot care products, uses 3D printing to create custom orthotics.

2. Logistics

Smart logistics powered by connectivity, advanced analytics and automation solutions encompass route optimisation and vehicle scheduling. Moreover, COVID-19 has increased the need to deploy fully autonomous vehicles to deliver goods and minimise physical interactions. The introduction of fully automated vehicles depends on deep learning algorithms, and the technology is not yet available.

Even though most vehicles still have to be controlled by human drivers, they are starting to adopt self-driving features. In 2019, an autonomous truck with a safety driver on board made a trip from California to Pennsylvania in three days. Such a trip would usually take nearly nine days. Unmanned aerial vehicles can also be used to optimise the delivery process and maintain social distancing. For example, Amazon developed a delivery system to distribute packages by drones in 30 minutes or less. Another example of no-contact delivery is self-driving robots. At the beginning of 2021, Starship Technologies’ delivery robots have already completed around a million autonomous deliveries.

3. Retail

With the rise of e-commerce, optimising operational costs with technology solutions is also growing. Digital supply chains powered by intelligent, data-based processes provide retailers with enhanced transparency, including raw material acquisition, production and last-mile delivery. By adopting intelligent, data-driven processes, retail software can not only help to effectively manage inventory and meet consumer expectations, but they can also synchronise information-sharing across the whole supply chain.

To learn more about the concept of the intelligent supply chain, check out our latest whitepaper - The Evolution of Retail Technology.

As such, retailers are now adopting a 360-degree view of their entire supply chain—from raw material acquisition to production to last-mile delivery. Zara, a fast-fashion retailer that also manufactures its clothing, uses RFID tags to produce more fast-selling clothes and avoid out-of-stock situations. Walmart has invested $14 billion to improve its supply chain, leveraging automation solutions in distribution centres.

Final thoughts

More than 80% of organisations are preparing to leverage the digital ecosystem in the next few years. Many partner with third-party software vendors to build up smart development teams skilled to drive digital transformation forward. Digitisation is a win-win solution for all supply chain stakeholders. The adoption of cutting-edge technologies allows companies to stay responsive to the changing business environment, deliver excellent customer experience and stay ahead of competitors.

Related Insights

The breadth of knowledge and understanding that ELEKS has within its walls allows us to leverage that expertise to make superior deliverables for our customers. When you work with ELEKS, you are working with the top 1% of the aptitude and engineering excellence of the whole country.

Right from the start, we really liked ELEKS’ commitment and engagement. They came to us with their best people to try to understand our context, our business idea, and developed the first prototype with us. They were very professional and very customer oriented. I think, without ELEKS it probably would not have been possible to have such a successful product in such a short period of time.

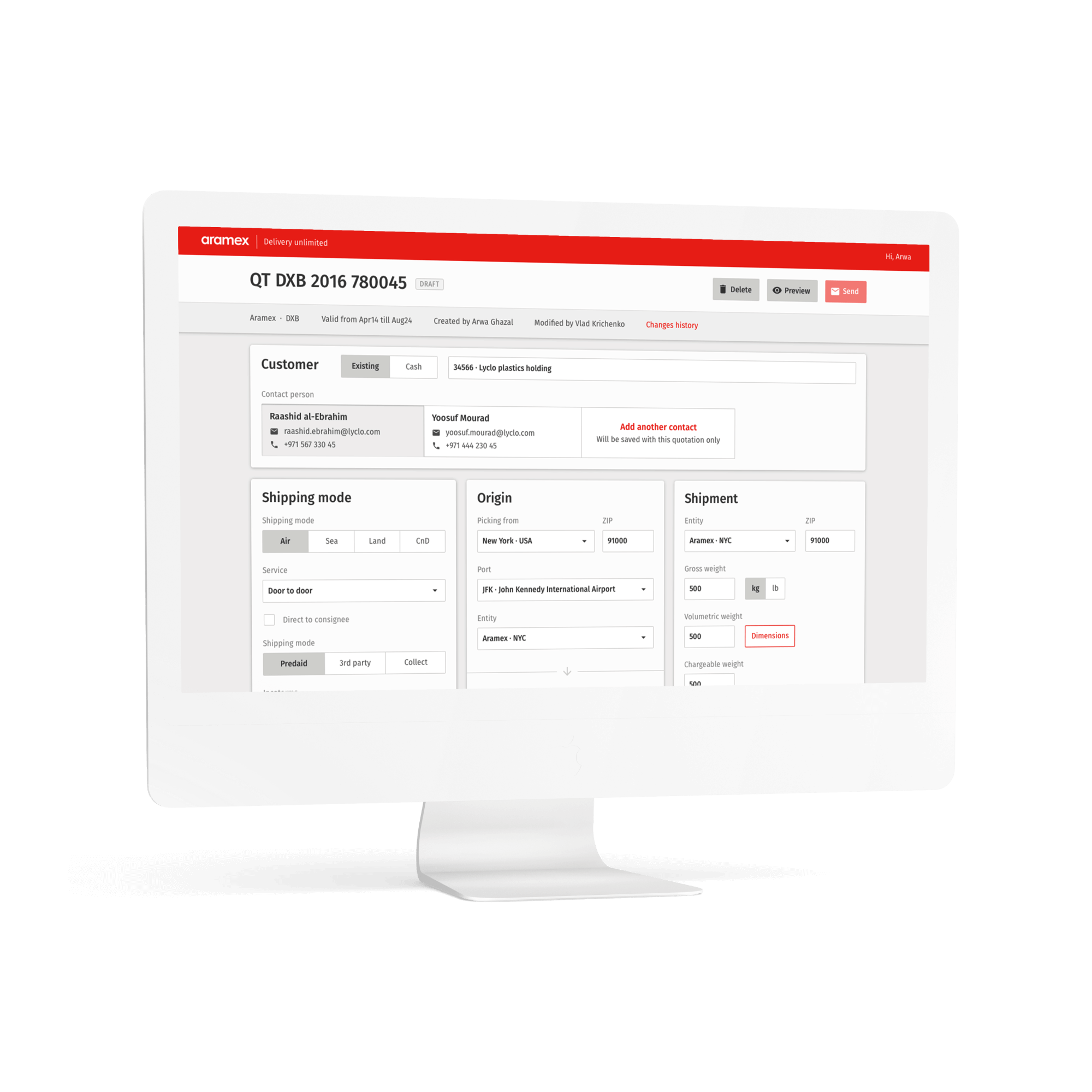

ELEKS has been involved in the development of a number of our consumer-facing websites and mobile applications that allow our customers to easily track their shipments, get the information they need as well as stay in touch with us. We’ve appreciated the level of ELEKS’ expertise, responsiveness and attention to details.