- Learn how machine learning is actively solving real-world challenges in manufacturing.

- ML helps manufacturers save costs, reduce downtime, and improve product quality with real data-driven intelligence.

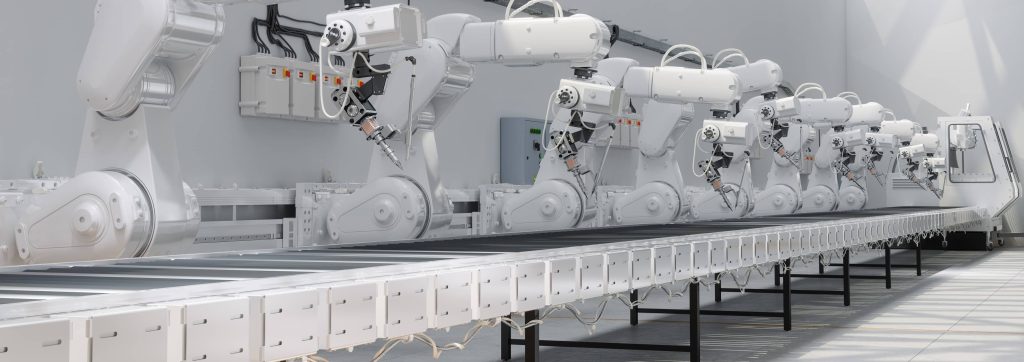

- Machine learning is a force behind Industry 4.0, boosting efficiency and competitiveness in manufacturing.

However, integrating machine learning into manufacturing processes is not just about automation—it’s about smart automation. It holds great potential for improving efficiency, reducing waste and enhancing product quality. Let’s delve more into the multifaceted implications of this technology.

What is machine learning?

First, let’s define what we mean by machine learning and the various forms it can adopt. As a subset of artificial intelligence, machine learning is the process of training computers to think like human beings. This means giving them the inputs—i.e. vast quantities of real-world data—to develop their own autonomous “thought processes” over time.

For example, machine learning algorithms are presented with images containing cardboard boxes and those without. After a while, the ML algorithm becomes adept at recognising the distinctive features of a cardboard box. Thus, ML algorithms are not simply introduced to the concept of a cardboard box; instead, they are provided with all the necessary information that allows them to grasp the characteristics and identify a cardboard box autonomously.

Various machine learning algorithms are categorised based on their learning approaches. The learning style of each algorithm differs according to the way it processes data and whether this data is labelled or unlabelled. Machine learning is generally classified as supervised, unsupervised or semi-supervised and reinforcement learning.

Types of machine learning models used within manufacturing

Can be trained, using predefined criteria, to identify patterns in data. This is typically applied using one of two models:

- Regression model - which analyses historical data sets to predict things like how long a machine component is likely to last, based on previous experience. This is known as the Remaining Useful Lifespan—or RUL.

- Classification model – this type of model can predict the likelihood of a machine or component failure within a predefined period, as an example.

Infers its own patterns from sets of data without any predefined outcomes and, therefore, can’t be trained in the same way as supervised learning. Common applications include:

- Clustering - Creates clusters of different data points linked by certain attributes to identify patterns.

- Anomaly detection - can identify unusual patterns within a dataset—i.e. fraudulent behaviour or, in manufacturing, faulty components.

- Association mining - is typically used in retail to pinpoint sets of items that often occur together in a basket.

- Latent variable models - generally used in data preprocessing—i.e. to reduce the number of points in a dataset.

Six applications of machine learning in manufacturing

Machine learning solutions have been developed for various applications in the manufacturing industry, including data analytics, quality assesment, and others. Here are some of the top machine learning applications in manufacturing operations that are helping to revolutionise the sector.

1. Predictive maintenance

Predictive maintenance is one of the key use cases for ML in manufacturing because it can preempt the failure of vital machinery or components using algorithms.

By analysing data from previous maintenance cycles, machine learning can identify patterns that can be used to predict equipment failures and when future maintenance will be needed. This information can then be used to schedule maintenance before problems occur. This, in turn, could save manufacturers significant time and money since it allows them to tackle specific issues exactly when needed—and in a highly focused way. This benefits manufacturers by:

- significantly reducing planned and unplanned downtime and, thus, costs.

- providing technicians with focused inspection, repair and tool requirements.

- prolonging the remaining useful life (RUL) of machinery by preventing any secondary damage during repairs.

- reducing the size of the technical team needed to make repairs.

However, even with the best algorithm, predictive quality analytics will only be as effective as the data that is used to train it. In order to be successful, manufacturers must have a well-designed data collection strategy that captures all relevant information about their process.

2. Predictive quality and yield

As consumer demand grows in line with an expanding population, process-based losses are becoming harder for manufacturers to tolerate. AI and machine learning can enable businesses to get to the root cause of losses related to quality, yield, energy efficiency and so on, thereby protecting their bottom line and enabling them to remain competitive. It does so using continuous, multivariate analysis via process-tailored ML algorithms, and also through machine learning-enabled Root Cause Analysis (RCA).

ML and AI-driven RCA, in particular, is a powerful tool for tackling process-based wastage and is far more effective than manual RCA for the following reasons:

- With automated RCA, machine learning algorithms harness historical data models to identify patterns in new data and make predictions on where losses may be occurring—preempting issues ahead of time.

- This method, over manual RCA, is entirely data-driven and completely unbiased.

- It’s also unclouded by daily admin and other manual tasks performed by process experts, so the focus is purely on optimising processes.

3. Digital twins

A digital twin—a real-time digital representation of a physical object or, indeed, a process—can be used by manufacturers to carry out instant diagnostics, evaluate production processes, and make performance predictions. But more than this, digital twins can help manufacturers revolutionise their engineering practices while offering full design, production and operational customisation. So, in other words, manufacturing companies can create a virtual representation of their products and processes, which can be used to test and optimise them before they are built. The benefits of ML-enabled digital twins in manufacturing include:

- significant cost reductions

- improved reliability of production lines

- optimised performance and productivity

- reduced risks on the shop floor

- improved quality and full customisation

- streamlined maintenance

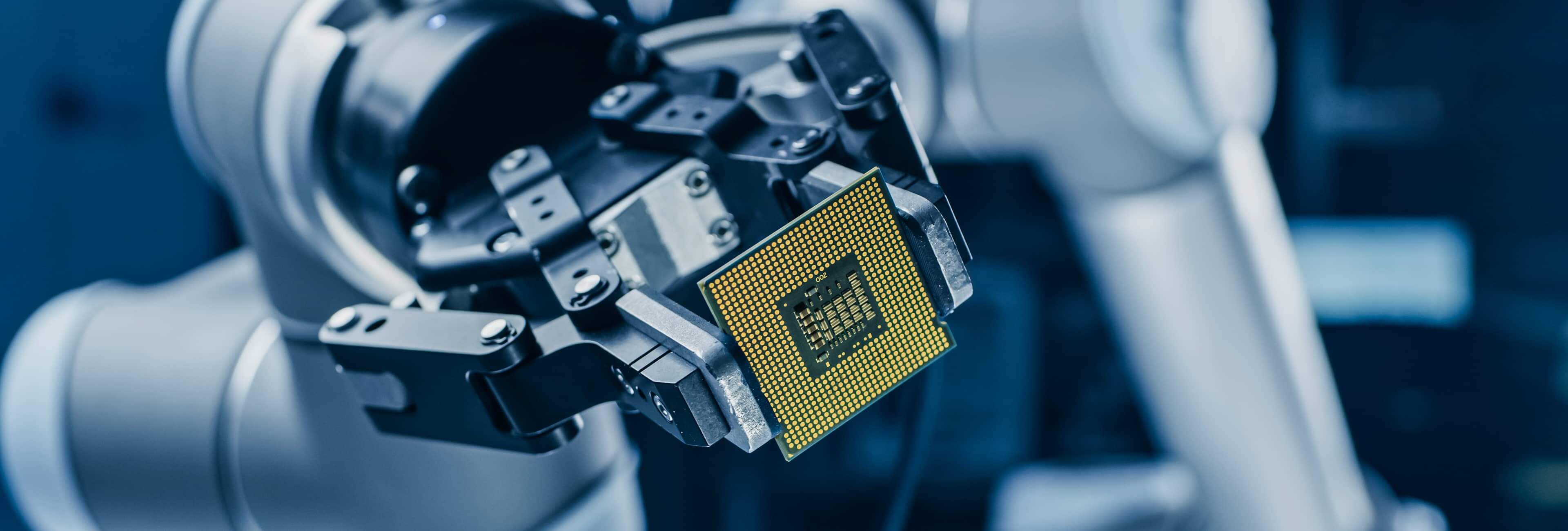

4. Generative design / smart manufacturing

Artificial intelligence, particularly generative AI, and machine learning have the capability to create an almost infinite number of design solutions to match any problem/product based on preset factors like size, materials, weight, etc. This allows engineers to find the very best design solution for a product before it goes into production. Machine learning uses generator and discriminator models to:

- create new designs for specified products

- distinguish between generated and real products

- train deep learning algorithms to recognise and define every possible design solution, thus optimising the design for a specified task

- make the computer a “design partner.”

5. Energy consumption forecasting

Manufacturers can now use machine learning algorithms that process data on factors like temperature, lighting, activity levels within a facility and more to build predictive models of likely energy consumption in the future. Machine learning algorithms can analyse large data sets to identify patterns and relationships that would be difficult to find using traditional methods. They do this using:

- Sequential data measurements.

- Autoregressive data models that identify cyclical/seasonal trends - data scientists will often pair this approach with feature engineering, which turns raw and unordered data into “features” for algorithms to define and build predictive analytics models on.

- Deep neural networks - which can process vast quantities of data and rapidly identify patterns.

Forecasting energy consumption is important for manufacturing for a number of reasons. First, it can help factory owners and operators plan for future energy needs. This planning is essential to ensuring that factories have the necessary resources to meet production demands. Additionally, forecasting energy consumption can help factories avoid disruptions in production due to unexpected changes in energy costs or availability.

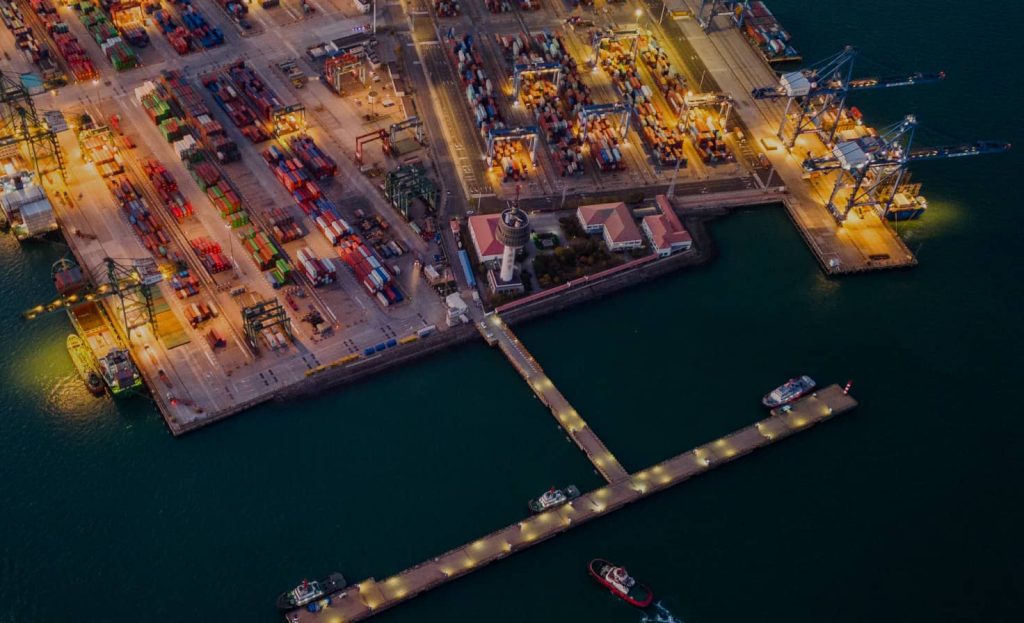

6. Cognitive supply chain management

With the proliferation of IIoT technologies, it’s only a matter of time before smart supply chains completely redefine how manufacturers carry out their operations. Automation is the first rung on the ladder, but soon entire supply chains could be “cognitive”. This means that they can use AI and machine learning algorithms to perform automatic analysis of datasets, including inbound and outbound shipments, inventory, consumer preferences, market trends, and even weather forecasts for predicting optimal shipping conditions.

- Key areas enhanced by cognitive supply chain management will be:

-

- Warehouse control – stock control facilitated by deep learning-based computer vision systems, enabling the rapid replenishment of supplies.

- Demand forecasting – the analysis of customer behaviours and preferences using time series analysis, feature engineering, and NLP techniques.

- Logistics route optimisation – manufacturers can review and allocate the most optimal routes for shipping goods using machine learning algorithms.

- Transport optimisation – assessing impacts on shipments and deliverables using machine and deep learning algorithms to optimise transportation solutions.

Benefits of machine learning for manufacturing

The potential benefits of ML within the sector are huge, and a trusted technology partner can help you seize them to the fullest. Businesses looking to implement machine learning models often partner with experienced AI development vendors. Such cooperation allows to leverage development teams with data science expertise and corresponding domain knowledge.

Companies leverage Machine Intelligence (MI) technologies to significantly enhance a wide range of performance indicators, achieving impacts that are three to four times greater than those of average players in the industry.

Some of the most compelling reasons to employ machine learning and artificial intelligence within manufacturing are:

- Significant process-driven loss reductions.

- Cost reductions driven by predictive maintenance.

- Consumer-driven product creation thanks to smart factories.

- Boost in capacity through process optimisation.

- Ability to scale product lines by streamlining and optimising processes.

- More efficient inventory management by using predictive analytics.

- Extended life of machinery and equipment via Predicting Remaining Useful Life (RUL).

- Better supply chain management.

- Enhanced quality control.

- Improved safety conditions on the manufacturing floor with the help of deep learning techniques implementation.

By harnessing the power of data, machine learning can help factories optimise the entire production process and reduce wastage. In the future, machine learning will play an even bigger role in the manufacturing industry, as it continues to evolve and become more sophisticated.

Ready to revolutionise your manufacturing business with AI and ML? ELEKS Data Science Platform can help you realise your vision.

FAQs

Machine learning helps optimise production by analysing data for quality control, predictive maintenance, and process improvements.

AI in manufacturing will drive automation, reduce downtime, enhance quality, and enable real-time decision-making across operations.

Industry 4.0 refers to the integration of AI, IoT, and smart systems to create automated and data-driven manufacturing environments.

Smart manufacturing technology uses SCADA systems, sensors, and AI in manufacturing for monitoring, predictive insights, and adaptive automation.

Related Insights